Table of Contents

RFID laundry tags are widely used in the textile industry. Through real-time data network connection, full life cycle management and standardized management of textiles are realized. UHF RFID laundry tags are waterproof, moisture-proof, high-temperature, and wash-resistant, and can be easily implanted into textiles to provide high-quality assurance. RFID laundry management system benefits include reducing manual fabric sorting, providing accurate records of cleaning quantities, quick and easy inventory management visualization, reducing lost and stolen fabrics, and providing meaningful customer information. Through RFID technology, it is possible to automatically identify target objects and access relevant data, improve management efficiency, and promote the development of the laundry industry!

Textile Management with RFID Technology

In each piece of textile (fabric) implanted with RFID chip RFID laundry tags or laundry coins, for their identity authentication, chip data real-time networking, so that not only can let the leasing party (service industry, hotels, hospitals, beauty salons) at any time and place to know each textile (fabric) materials, specifications, sizes, and has been washed a number of times and so on the information; and textile in the receiving and sending, washing, drying, ironing, folding, packing, transportation and so on the whole process of real-time data reading and monitoring, realize the textile whole life cycle management, standardized management And textiles in the sending and receiving, washing, drying, ironing, folding, packing, transportation and other processes in the real-time data reading and monitoring, the realization of the textile life cycle management, standardized management of fabric washing, fast inventory, intelligent sorting, fabric traceability, and is conducive to protect the provision of high-quality services.

Benefits of UHF RFID Washing Tags in the Laundry Industry

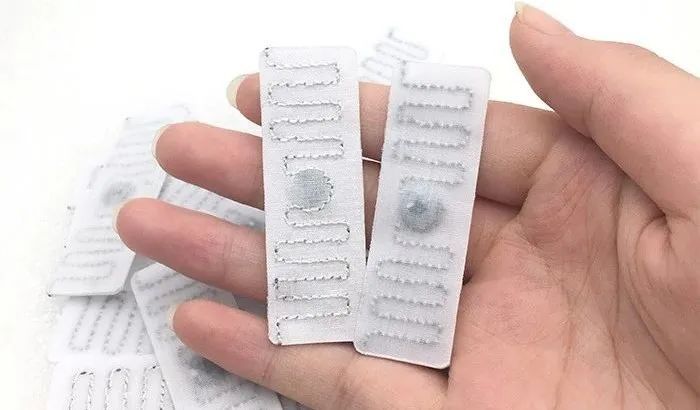

UHF RFID washing tags are widely used in the washing industry, because it is waterproof, moisture-proof, UHF, high temperature, water washing resistance, etc., can be easily implanted into the textiles (fabric), only through sewing or hot ironing, each tag ID is unique, high quality assurance.

RFID washing management system advantages

Reduced Labor Fabric Sorting

When an RFID tag passes through the assembly line, the RFID reader sends a query signal and reads the tag. After all tags have been read, the system will confirm what type of fabric is being read and send the fabric to the appropriate place or machine. The results of the system's processing are displayed on the screen, making it easy for you to send your fabrics to the next location immediately. Enterprises in the current use of RFID can be eliminated manpower fabric sorting and thus significantly reduce the cost of fabric sorting on the manpower expenditure. Instead of relying on the human eye to distinguish barcodes or area fabrics, now only 1-2 people need to be assigned to send the fabrics to the next process in an organized manner.

Provides an accurate record of cleaning quantities

Most fabrics can only withstand a certain number of intense wash cycles, after which they begin to break down or become damaged. The number of wash cycles per fabric is an important piece of data, and a wash cycle analysis system can effectively help predict the end of life date of each piece of fabric. This also makes it easier for hotels to plan their ordering for replacement of old fabrics, which greatly reduces the time it takes to replenish lost or damaged fabrics.

Provide quick and easy visualization of inventory management

Lack of inventory visibility can make it difficult to accurately plan for emergencies, operate efficiently, or prevent fabric loss and theft. If a piece of fabric is stolen and the organization does not have a daily inventory audit, it may be exposed to potential delays in daily operations due to inaccurate inventory management.

RFID tags sewn into each piece of fabric can help organizations manage inventory faster and more efficiently on a daily basis. RFID readers placed in each warehouse provide continuous inventory monitoring to help pinpoint where fabric is missing or stolen. Inventory count readings via RFID can also help organizations that use outsourced cleaning services. Inventory counts are read before the fabrics are sent away to be washed, and again when the fabrics are returned to ensure that no fabrics are lost during the final wash.

Reduce Lost and Stolen Fabrics

Most organizations around the world are still using simple, labor-dependent inventory management methods to try to count lost or stolen fabric. Unfortunately, the human error involved in manually counting hundreds or thousands of pieces of fabric is significant. Once the count is complete, the next step is to try to find out where the holes in the system are. Typically, when a piece of fabric is stolen, it is virtually impossible for an organization to locate the thief, much less receive compensation or reimbursement.

The unique identifier within the RFID tag gives the organization the ability to identify exactly which piece of fabric was lost or stolen, and to know where it was last located. If a piece of fabric is taken out of a room in a hotel or hospital, the guest in that room can be charged extra for the fabric to ensure that the organization does not lose money.

Provide meaningful customer information

Fabric rental businesses have a unique way to study user behavior and learn about their customers through RFID tags on rental fabrics. RFID tags sewn into the fabric help record customer information, such as historical renters, dates of rental, length of rental, and more. Keeping these records helps organizations understand product popularity, product history and customer preferences.

Accurate check-in and check-out system management

The process of fabric rental is usually very complicated unless the organization can set up a simple concept of keeping information such as rental date, expiration date, customer information, etc. The RFID system provides an easy way to keep track of the rental date, expiration date, and customer information. RFID systems provide a customer database that not only stores important information, but also allows for timely and accurate check-in and check-out.

RFID through the radio frequency automatic identification of the target object and access to relevant data, identification work without human intervention, reducing the error rate of the traditional manual operation time, greatly improving the management efficiency, RFID intelligent washing and green washing to boost the development of the washing industry!

Conclusion

In conclusion, RFID technology in the textile industry, especially in fabric management and laundry services, brings significant benefits like improved inventory control, operational efficiency, and customer service. By integrating RFID tags into fabric, organizations can streamline inventory processes, cut labor costs, and enhance traceability. Real-time monitoring ensures accurate inventory, reduces losses, and enables quick responses. Unique RFID identifiers track fabric movement precisely, enhancing security. Overall, RFID implementation boosts efficiency, customer satisfaction, and sets the path for a sustainable future in laundry services.