RFID storage label

The modern information management system requires the characteristics of paperless, orderly, standardized and intelligent management. With the continuous development of RFID technology, this application has also been introduced in warehouse management. It is attached to the goods as an electronic label and is mainly used for information storage of goods. Compared with barcode technology, it is more intelligent, just like The "identity card" of the goods.

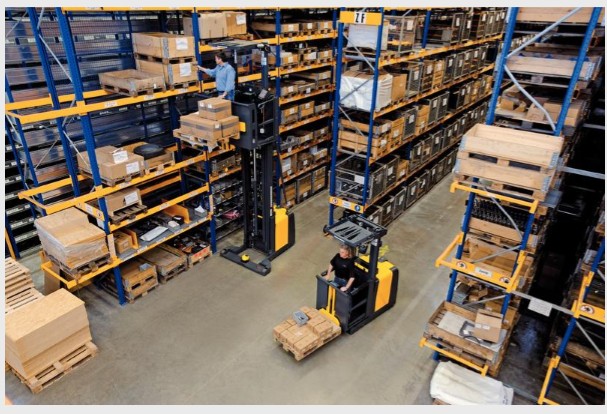

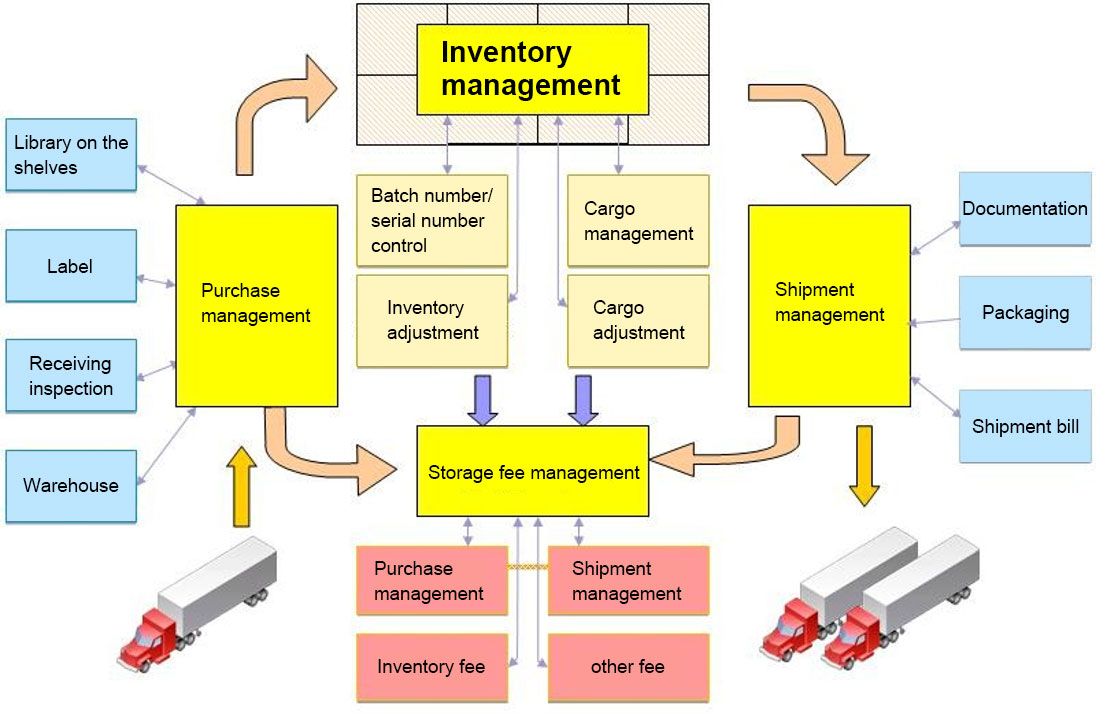

RFID warehousing management is to introduce RFID technology into the existing warehousing management, and automatically collect data from various operation links such as warehouse arrival inspection, warehousing, outbound, transfer, warehouse shifting, inventory inventory, etc., to ensure warehouse management. The speed and accuracy of data collection in each link ensures that the enterprise can grasp the real inventory data in a timely and accurate manner, and maintain and control the enterprise inventory reasonably.

Intelligent warehouse management system based on RFID technology

Huahao RFID intelligent warehouse management system is a real-time warehouse operation management system specially designed for enterprise warehouses or distribution centers based on RFID technology. The system covers order management, picking management, receiving management, warehouse transfer management, replenishment management, inventory management, transportation management, supplier management and report management, etc., to realize intelligent warehouse management.

Storage:

The location, quantity, specification and model of each item in the warehouse can be clearly displayed in the warehouse management software, realizing the visualization of the warehouse status. After the warehousing operation is completed, a warehousing product data sheet should be generated to record the name, type, production date, warehousing time, warehousing batch, quality status, warehousing quantity, warehousing handler, and warehouse code of the warehousing product and other information for inquiries.

Outbound:

Use the access door (RFID fixed reader) to communicate with the tag, collect the RFID electronic tag of the goods out of the warehouse, check whether it corresponds to the delivery order, and if there is an error, manually process it as soon as possible. For a small amount of goods, PDA can be used to collect information on RFID electronic tags. When errors occur, the staff should deal with them in a timely manner, and finally send the data to the management center to update the database to complete the delivery.

inventory:

In accordance with the requirements of warehouse management, carry out regular and irregular inventory. Use the RFID handheld terminal to scan the inventory of the goods, and the information of the inventory can be transmitted to the background database through the wireless network, and compared with the information in the database, the generated difference information is displayed on the RFID handheld terminal in real time, and the inventory work is provided. Personnel verification. RFID technology reduces manpower during inventory counting, realizes warehousing automation, is faster and more accurate, and reduces corresponding time.

The RFID warehouse

management system covers the core warehousing, inventory, transfer, transfer, etc., as well as a series of basic information, report and other functions, with reliable transmission, intelligent control, data fusion, real-time recording, integrated docking, data analysis, etc. Multi-faceted application value.